Computer hardware inventory management is a critical process for organizations of all sizes. It involves tracking and managing all physical IT assets , from desktops and laptops to servers and networking equipment. Without an effective system in place , businesses can face a scope of challenges , including wasted resources , boostd security risks , and compliance issues. What exactly is computer hardware inventory management , and why is it so crucial? Simply put , it’s the systematic approach to knowing what hardware you have , where it is , and how it’s being used.

Many organizations struggle with outdated or inaccurate inventory data , leading to inefficient resource allocation and unnecessary expenses. Imagine trying to manage a fleet of vehicles without knowing which ones are operational , where they are located , or when they need maintenance. The same principle applies to computer hardware. This article will explore the key facets of computer hardware inventory management , providing practical strategies and optimal practices to help you maximize your IT infrastructure. We’ll cover everything from implementing an inventory system to leveraging automation and cloud solutions , ensuring that you have the tools and knowledge to maintain an accurate and efficient hardware inventory. By the end of this guide , you’ll have a clear understanding of how to streamline your hardware management processes , reduce costs , and enhance security. Let’s dive in and transform your approach to computer hardware inventory management! This article is structured to offer a thorough overview , starting with the basics and progressing to more advanced strategies. We’ll cover:

- Understanding Computer Hardware Inventory Management

- Implementing a Computer Hardware Inventory System

- Optimizing Hardware Lifecycle Management

- Leveraging Automation and Cloud Solutions

- optimal Practices for Maintaining an Accurate Inventory

This structured approach will equip you with the knowledge and tools necessary to effectively manage your computer hardware inventory.

Understanding Computer Hardware Inventory Management

What is Computer Hardware Inventory Management?

Computer hardware inventory management is the process of tracking and managing all physical IT assets within an organization. This includes desktops , laptops , servers , networking equipment , peripherals , and other hardware components. Effective inventory management involves maintaining an accurate record of each asset’s location , configuration , warranty status , and lifecycle stage. This thorough approach enables organizations to maximize resource allocation , minimize costs , and enhance security.

Why is Hardware Inventory Management crucial?

Effective hardware inventory management is crucial for several reasons:

- Cost Reduction: By accurately tracking hardware assets , organizations can avoid unnecessary purchases , determine underutilized equipment , and maximize maintenance schedules. This leads to significant cost savings over time.

- Enhanced Security: Knowing the location and configuration of all hardware assets allows IT teams to quickly determine and address security vulnerabilities. This is particularly crucial in today’s threat landscape , where compromised devices can serve as entry points for cyberattacks.

- Improved Compliance: Many industries are subject to regulatory requirements that mandate accurate tracking of IT assets. Effective hardware inventory management helps organizations comply with these regulations and avoid costly penalties.

- Efficient Resource Allocation: With a clear understanding of available hardware resources , IT departments can allocate equipment more efficiently , ensuring that employees have the tools they need to perform their jobs effectively.

- Better Decision-Making: Accurate inventory data offers valuable insights that can inform strategic decision-making related to IT investments , upgrades , and replacements.

Key Components of a Hardware Inventory Management System

A robust hardware inventory management system typically includes the following components:

- Asset Tracking Software: This software automates the process of determineing , tracking , and managing hardware assets. It often includes attributes such as barcode scanning , RFID tagging , and automated discovery tools.

- Centralized Database: A centralized database serves as a repository for all hardware inventory data. This ensures that information is accurate , up-to-date , and accessible to authorized personnel.

- Reporting and Analytics: Reporting and analytics tools offer insights into hardware utilization , costs , and trends. This information can be used to maximize resource allocation and make informed decisions about IT investments.

- Lifecycle Management: Lifecycle management tools help organizations track the entire lifecycle of hardware assets , from procurement to disposal. This includes managing warranties , maintenance schedules , and end-of-life planning.

Challenges in Hardware Inventory Management

Despite its importance , hardware inventory management can be challenging , particularly for large organizations with complex IT environments. Some common challenges include:

- Manual Tracking: Relying on manual spreadsheets or paper-based systems is time-consuming , error-prone , and difficult to scale.

- Lack of Automation: Without automated tools , it can be difficult to keep track of hardware assets in real-time.

- Data Silos: When hardware inventory data is stored in multiple systems or departments , it can be difficult to get a complete and accurate picture of the organization’s IT assets.

- Mobile Devices: Tracking mobile devices such as laptops and smartphones can be particularly challenging , as these devices are often used outside of the organization’s network.

- Integration Issues: Integrating hardware inventory management systems with other IT systems , such as help desk software and asset management tools , can be complex and time-consuming.

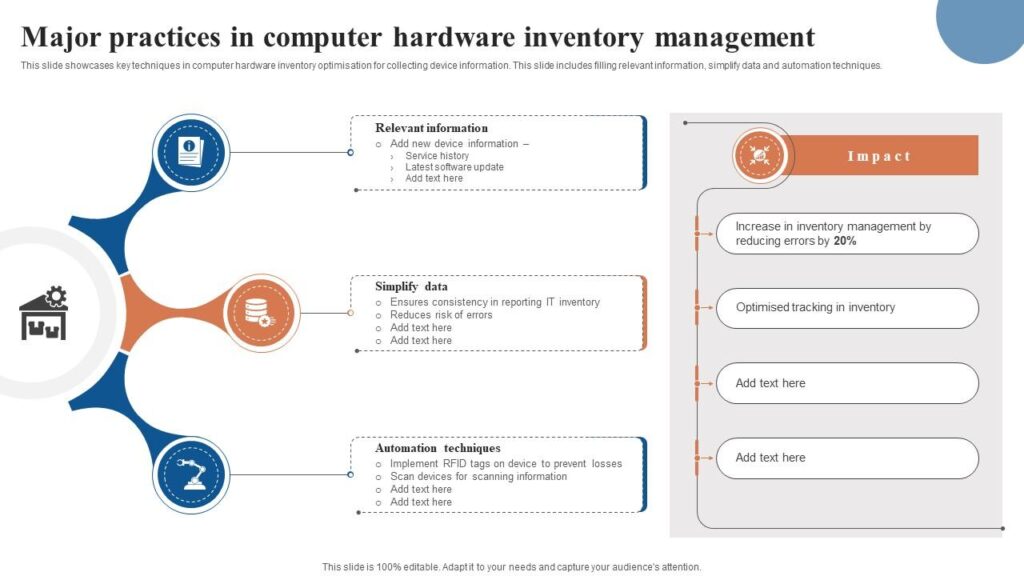

optimal Practices for Effective Hardware Inventory Management

To overcome these challenges and ensure effective hardware inventory management , organizations should follow these optimal practices:

- Implement Automated Tracking Tools: Invest in asset tracking software that automates the process of determineing , tracking , and managing hardware assets.

- Centralize Data: Store all hardware inventory data in a centralized database that is accessible to authorized personnel.

- Establish Clear Policies and Procedures: Develop clear policies and procedures for hardware procurement , deployment , maintenance , and disposal.

- Regularly Audit Inventory: Conduct regular audits to ensure that hardware inventory data is accurate and up-to-date.

- Integrate with Other IT Systems: Integrate hardware inventory management systems with other IT systems to streamline workflows and improve data accuracy.

- Train Employees: offer training to employees on hardware inventory management policies and procedures.

By addressing these challenges and implementing these optimal practices , organizations can improve their hardware inventory management processes and realize the benefits of reduced costs , enhanced security , and improved resource allocation.

Implementing a Computer Hardware Inventory System

Choosing the Right Inventory Management Software

selecting the appropriate inventory management software is a critical step in establishing an effective system. The industry offers a variety of solutions , ranging from basic asset tracking tools to thorough IT management platforms. When evaluating software options , consider the following factors:

- Scalability: The software should be able to scale to accommodate the organization’s current and future needs.

- attributes: The software should offer the attributes and functionality required to manage the organization’s hardware assets effectively. This may include barcode scanning , RFID tagging , automated discovery , reporting , and analytics.

- Integration: The software should integrate seamlessly with other IT systems , such as help desk software , asset management tools , and financial systems.

- Ease of Use: The software should be easy to use and intuitive , with a user-friendly interface that requires minimal training.

- Cost: The software should be affordable and offer a good return on investment.

Some popular hardware inventory management software options include:

- SolarWinds Service Desk: A thorough IT service management platform that includes asset discovery , inventory management , and help desk functionality.

- ManageEngine AssetExplorer: An asset management solution that offers detailed information about hardware and software assets , including warranty status , license compliance , and application statistics.

- Lansweeper: A network inventory and asset management tool that automatically discovers and tracks hardware and software assets on the network.

- Snipe-IT: An open-source asset management system that is designed to be simple , flexible , and easy to use.

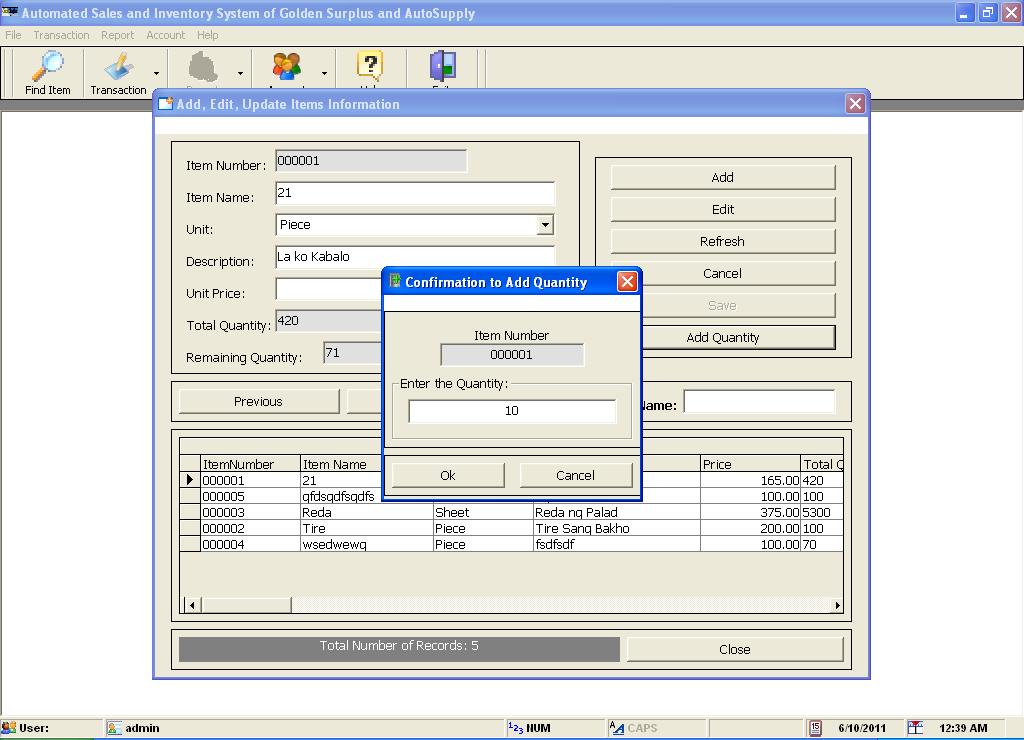

Setting Up the Inventory Database

Once you have selected the appropriate software , the next step is to set up the inventory database. This involves creating a structure for storing hardware asset data and defining the fields that will be used to track each asset. Some common fields include:

- Asset Tag: A unique identifier for each hardware asset.

- Serial Number: The manufacturer’s serial number for the asset.

- Asset Name: A descriptive name for the asset.

- Asset Type: The type of hardware asset (e.g. , desktop , laptop , server).

- Manufacturer: The manufacturer of the asset.

- Model: The model of the asset.

- Location: The physical location of the asset.

- User: The user assigned to the asset.

- Purchase Date: The date the asset was purchased.

- Warranty Expiration Date: The date the warranty expires.

- Operating System: The operating system installed on the asset.

- Software Installed: A list of software installed on the asset.

- IP Address: The IP address of the asset.

- MAC Address: The MAC address of the asset.

When setting up the inventory database , it is crucial to establish clear naming conventions and data entry standards to ensure consistency and accuracy.

Populating the Inventory Database

After setting up the inventory database , the next step is to populate it with data. This can be done manually or automatically , depending on the capabilities of the inventory management software. Manual data entry can be time-consuming and error-prone , but it may be necessary for assets that cannot be automatically discovered. Automated discovery tools can scan the network and determine hardware assets , automatically populating the inventory database with data. Some software solutions also support barcode scanning and RFID tagging , which can further streamline the data entry process.

Integrating with Other IT Systems

Integrating the hardware inventory management system with other IT systems can offer significant benefits. For example , integrating with help desk software can enable IT staff to quickly access hardware inventory data when troubleshooting issues. Integrating with asset management tools can offer a more thorough view of the organization’s IT assets. Integrating with financial systems can help track hardware costs and depreciation. When integrating with other IT systems , it is crucial to ensure that data is synchronized and consistent across all systems.

Training and Documentation

To ensure that the hardware inventory management system is used effectively , it is crucial to offer training to IT staff and other users. Training should cover the following topics:

- How to use the inventory management software.

- How to enter and update hardware asset data.

- How to generate reports and analyze data.

- Hardware inventory management policies and procedures.

In addition to training , it is crucial to create thorough documentation that outlines the hardware inventory management system , policies , and procedures. This documentation should be readily available to all users.

Optimizing Hardware Lifecyle Management

Procurement and Deployment

The hardware lifecycle begins with procurement and deployment. Establishing a standardized procurement process ensures that hardware assets are acquired in a cost-effective and efficient manner. This includes defining hardware standards , negotiating favorable pricing with vendors , and establishing clear procurement policies. During deployment , it is crucial to properly configure and document each hardware asset. This includes installing the operating system , software , and security patches , as well as assigning the asset to a user and location. Proper documentation ensures that hardware assets can be easily tracked and managed throughout their lifecycle.

Maintenance and Support

Regular maintenance and support are essential for extending the lifespan of hardware assets and minimizing downtime. This includes performing routine maintenance tasks , such as cleaning , defragmenting hard drives , and updating software. It also includes providing technical support to users and resolving hardware issues in a timely manner. Establishing a service level agreement (SLA) with a hardware vendor or third-party support offerr can ensure that hardware issues are resolved quickly and efficiently.

Upgrades and Replacements

As hardware assets age , they may become obsolete or unable to meet the organization’s needs. When this occurs , it is necessary to upgrade or replace the hardware. Upgrading hardware can extend its lifespan and improve performance , but it may not always be cost-effective. Replacing hardware with newer models can offer significant performance improvements and reduce maintenance costs , but it can also be expensive. When deciding whether to upgrade or replace hardware , it is crucial to consider the cost , performance , and lifespan of the asset.

Disposal and Recycling

The final stage of the hardware lifecycle is disposal and recycling. When hardware assets reach the end of their useful life , it is crucial to dispose of them in a responsible and environmentally friendly manner. This includes wiping data from hard drives , removing asset tags , and recycling hardware components. Many organizations partner with certified e-waste recyclers to ensure that hardware assets are disposed of properly and in compliance with environmental regulations. Disposing of hardware assets properly can protect sensitive data , reduce environmental impact , and comply with legal requirements.

Integrating Lifecycle Management with Inventory Data

Integrating hardware lifecycle management with inventory data offers a thorough view of each asset’s status , from procurement to disposal. This integration enables organizations to:

- Track the total cost of ownership (TCO) of each hardware asset.

- determine assets that are nearing the end of their useful life.

- Plan for hardware upgrades and replacements.

- maximize hardware utilization and resource allocation.

- Ensure compliance with environmental regulations.

By integrating lifecycle management with inventory data , organizations can make informed decisions about hardware investments and maximize their IT infrastructure.

Leveraging Automation and Cloud Solutions

Automating Inventory Tracking

Automation is a key enabler of effective hardware inventory management. By automating tasks such as asset discovery , data entry , and reporting , organizations can reduce manual effort , improve data accuracy , and complimentary up IT staff to focus on more strategic initiatives. Some common automation techniques include:

- Automated Discovery Tools: These tools automatically scan the network and determine hardware assets , populating the inventory database with data.

- Barcode Scanning and RFID Tagging: These technologies enable IT staff to quickly and accurately track hardware assets using handheld scanners or RFID readers.

- Automated Reporting: Automated reporting tools can generate reports on hardware inventory data , providing insights into asset utilization , costs , and trends.

- Alerting and Notifications: Automated alerting and notification systems can notify IT staff when hardware assets are moved , modified , or reach the end of their warranty period.

Cloud-Based Inventory Management

Cloud-based inventory management solutions offer several benefits over traditional on-premises systems. These benefits include:

- Scalability: Cloud-based solutions can easily scale to accommodate the organization’s growing needs.

- Accessibility: Cloud-based solutions can be accessed from anywhere with an internet connection.

- Cost-efficacy: Cloud-based solutions typically have lower upfront costs and ongoing maintenance expenses.

- Security: Cloud-based solutions often have robust security attributes , such as data encryption and access controls.

- Integration: Cloud-based solutions can easily integrate with other cloud-based IT systems.

Some popular cloud-based hardware inventory management solutions include:

- Asset Panda: A cloud-based asset tracking and management platform that offers attributes such as barcode scanning , mobile access , and custom reporting.

- EZOfficeInventory: A cloud-based asset tracking solution that is designed for small and medium-sized businesses.

- InvGate Assets: A cloud-based IT asset management solution that offers attributes such as asset discovery , inventory management , and software license management.

Integrating with Cloud Infrastructure

For organizations that use cloud infrastructure , such as Amazon Web Services (AWS) or Microsoft Azure , it is crucial to integrate hardware inventory management with the cloud environment. This integration enables organizations to:

- Track hardware assets in the cloud.

- Monitor the performance and utilization of cloud resources.

- Manage cloud costs and maximize resource allocation.

- Ensure compliance with cloud security policies.

Cloud offerrs typically offer tools and services that can be used to track and manage hardware assets in the cloud. For example , AWS offers AWS Systems Manager , which offers attributes such as inventory management , configuration management , and patch management.

benefits of Automation and Cloud Solutions

By leveraging automation and cloud solutions , organizations can significantly improve their hardware inventory management processes and realize the following benefits:

- Reduced Manual Effort: Automation reduces the need for manual data entry and tracking , complimentarying up IT staff to focus on more strategic initiatives.

- Improved Data Accuracy: Automation minimizes the risk of human error , ensuring that hardware inventory data is accurate and up-to-date.

- Enhanced Efficiency: Automation streamlines hardware inventory management processes , improving efficiency and reducing costs.

- Better Visibility: Cloud-based solutions offer a centralized view of hardware assets , enabling organizations to track and manage their IT infrastructure more effectively.

- boostd Agility: Cloud-based solutions enable organizations to quickly adapt to changing business needs and scale their IT infrastructure as required.

optimal Practices for Maintaining an Accurate Inventory

Regular Audits and Reconciliation

Conducting regular audits is crucial for maintaining an accurate hardware inventory. Audits involve physically verifying the existence and location of hardware assets and comparing this information to the data in the inventory database. Any discrepancies should be investigated and resolved promptly. Reconciliation is the process of comparing hardware inventory data with other sources of information , such as purchase orders , invoices , and asset registers. This helps to determine missing or inaccurate data and ensure that the inventory database is complete and up-to-date.

Standardized Naming Conventions

Establishing standardized naming conventions for hardware assets is essential for maintaining an organized and easily searchable inventory. Naming conventions should be clear , consistent , and descriptive , making it easy to determine the type , location , and owner of each asset. For example , a naming convention for laptops might include the department , user , and serial number (e.g. , Sales-JohnDoe-12345). Standardized naming conventions can also be used for software , network devices , and other IT assets.

Documenting Changes and Updates

It is crucial to document all changes and updates to hardware assets , such as upgrades , repairs , and relocations. This documentation should include the date of the change , the nature of the change , and the person who performed the change. This information can be stored in the inventory database or in a separate document management system. Documenting changes and updates ensures that there is a clear audit trail of all hardware asset activity.

Assigning Responsibility and Accountability

Assigning responsibility and accountability for hardware inventory management is crucial for ensuring that the process is followed consistently and effectively. This involves designating individuals or teams to be responsible for tasks such as asset tracking , data entry , auditing , and reporting. These individuals should be trained on hardware inventory management policies and procedures and held accountable for maintaining the accuracy and completeness of the inventory database.

Employee Training and Awareness

Employee training and awareness are essential for promoting a culture of hardware inventory management within the organization. Employees should be trained on the importance of tracking hardware assets , the procedures for reporting changes , and the consequences of failing to comply with inventory management policies. Regular communication and reminders can help to reinforce these messages and ensure that employees are aware of their responsibilities.

Utilizing Mobile Apps for On-the-Go Tracking

Mobile apps can be a valuable tool for tracking hardware assets on the go. These apps allow IT staff to scan barcodes , update asset information , and perform audits using their smartphones or tablets. Mobile apps can also be used to track hardware assets that are located outside of the organization’s network , such as laptops and mobile devices. Some popular mobile apps for hardware inventory management include:

- Asset Panda Mobile App: A mobile app that allows users to track assets , perform audits , and generate reports from their smartphones or tablets.

- EZOfficeInventory Mobile App: A mobile app that allows users to scan barcodes , update asset information , and perform audits from their smartphones or tablets.

- InvGate Assets Mobile App: A mobile app that allows users to track assets , perform audits , and manage software licenses from their smartphones or tablets.

By following these optimal practices , organizations can maintain an accurate hardware inventory , reduce costs , and improve security.

In conclusion , effective computer hardware inventory management is not merely a logistical task , but a strategic imperative for modern organizations. By implementing robust tracking systems , leveraging automation , and fostering collaboration between IT and finance departments , businesses can maximize their hardware investments , reduce costs , and enhance operational efficiency. Embracing a proactive approach to hardware lifecycle management ensures that resources are utilized effectively , security risks are minimized , and the organization remains agile and rival in a rapidly evolving technological landscape. Take the next step today to streamline your hardware inventory and unlock the full potential of your IT infrastructure!